Top Builders

Explore the top contributors showcasing the highest number of app submissions within our community.

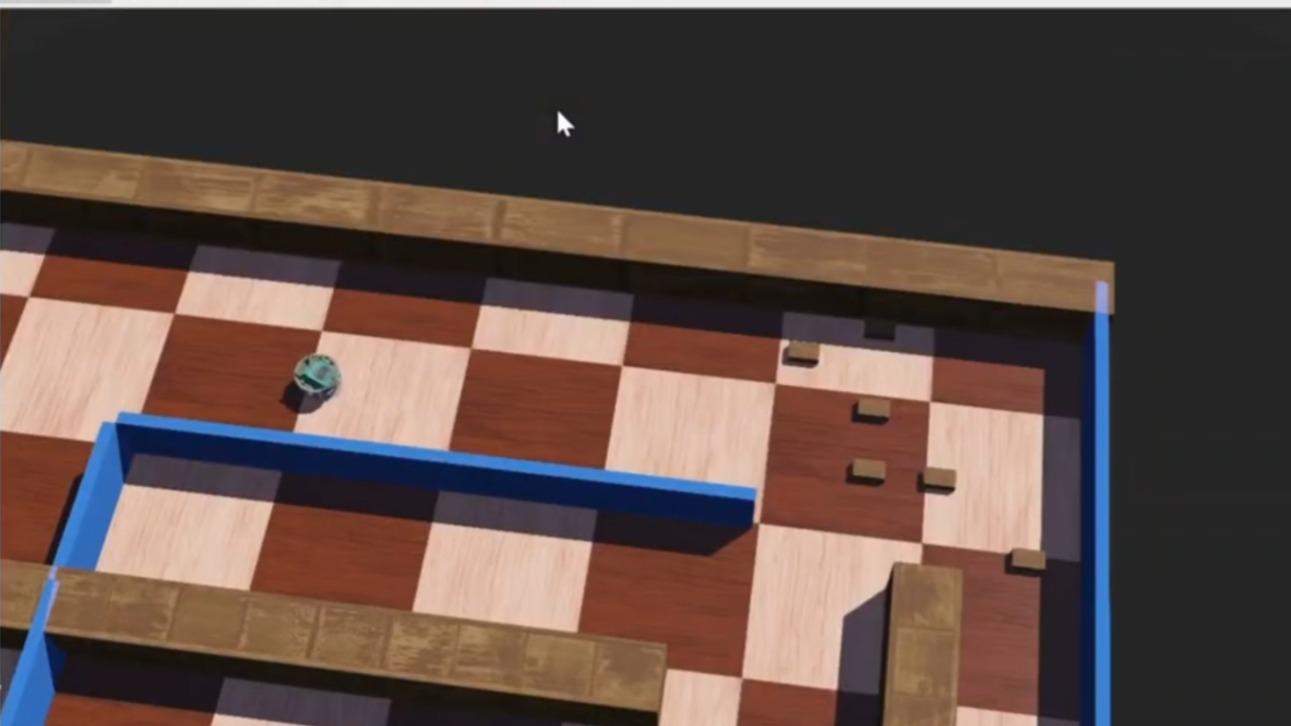

Webots

Webots is a professional, open-source 3D robot simulator that offers a comprehensive development environment for modeling, programming, and simulating robots. It is widely used for AI-driven control testing, allowing researchers and developers to design and evaluate robotic systems in a realistic virtual setting before deploying them in the physical world.

| General | |

|---|---|

| Author | Cyberbotics Ltd. |

| Release Date | 1998 |

| Website | https://cyberbotics.com/ |

| Documentation | https://cyberbotics.com/doc/guide/index |

| Repository | https://github.com/cyberbotics/webots |

| Technology Type | 3D robot simulator |

Key Features

- Realistic 3D Simulation: Provides accurate physics and rendering for a wide range of robot models and environments.

- Robot Modeling: Tools for designing and importing various robot types, sensors, and actuators.

- Programming Interface: Supports multiple programming languages (C/C++, Python, Java, MATLAB, etc.) for controlling robots.

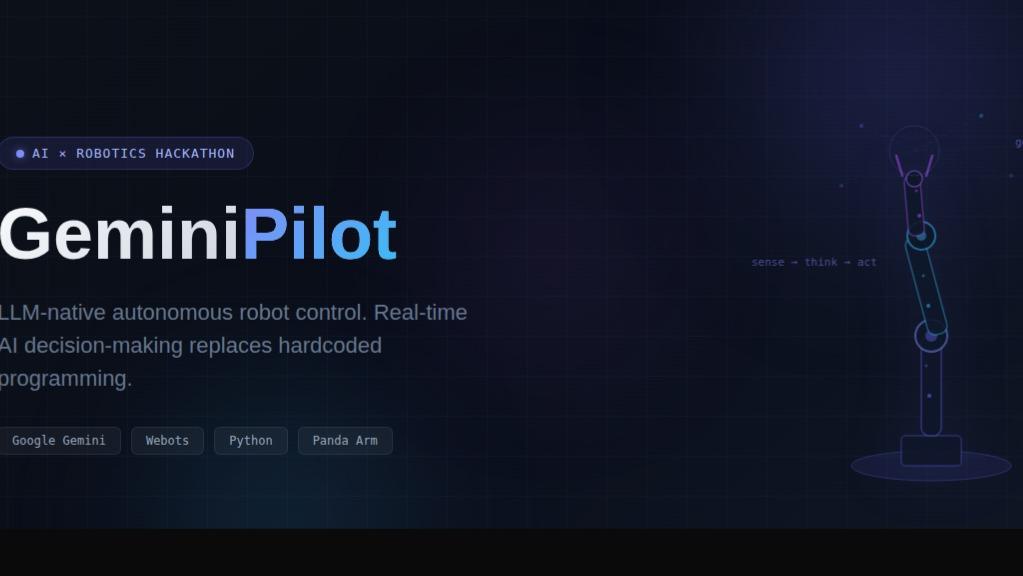

- AI Integration: Ideal for testing AI algorithms, machine learning, and neural networks in robotic control.

- Open-Source: Freely available for research and development, fostering community contributions.

- Cross-Platform: Runs on Windows, Linux, and macOS.

Start Building with Webots

Webots is an essential tool for anyone working on robotics and AI. Its ability to simulate complex robotic systems in a controlled environment allows for rapid prototyping, testing, and iteration of AI control algorithms. Explore the user guide and GitHub repository to get started with modeling your own robots and implementing AI-driven control strategies.

WEBOTS AI Technologies Hackathon projects

Discover innovative solutions crafted with WEBOTS AI Technologies, developed by our community members during our engaging hackathons.

.png&w=3840&q=75)