🤓 Latest Submissions

OpsTwin AI

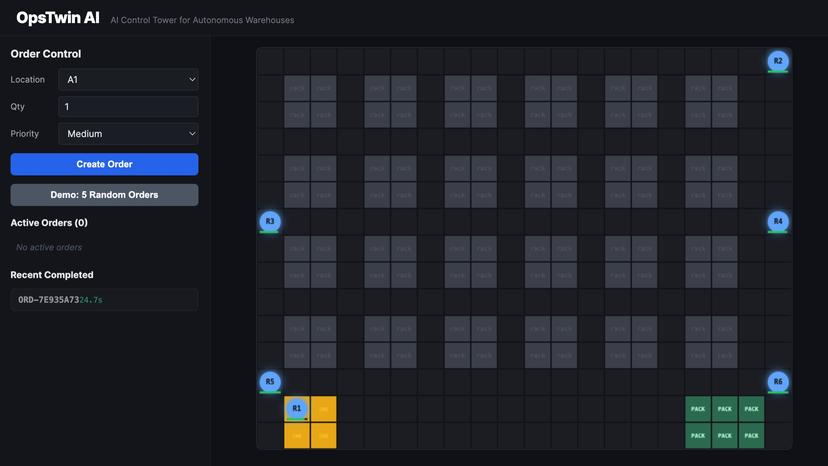

OpsTwin AI is a simulation-first autonomous warehouse control system designed to model and optimize multi-robot fulfillment operations. As warehouses adopt robotics at scale, fleet coordination becomes increasingly complex. Congestion, battery constraints, task prioritization, and workload balancing impact throughput and efficiency. OpsTwin AI addresses this by creating a digital twin of warehouse operations, a live simulation where robotic workflows can be orchestrated, tested, and optimized before real-world deployment. In OpsTwin AI, robots operate within a simulated warehouse grid containing storage racks, charging stations, and pack zones. When a new order is created, the system autonomously determines which robot should fulfill it. Instead of relying on hardcoded rules, I use Gemini as a strategic planning layer. The backend sends live fleet state, including robot positions, battery levels, and active tasks, to Gemini. Gemini returns structured JSON with a selected robot and step-by-step task sequence. This allows deterministic execution while enabling adaptive multi factor decision making. The Vultr-hosted backend serves as the centralized system of record. It maintains robot state, order queues, and operational metrics, and broadcasts real-time updates to a web dashboard using WebSockets. A 500 millisecond simulation loop executes plans, updates robot movement, tracks congestion events, and manages battery-aware charging. The result is fully autonomous multi-robot operation without manual intervention. From a business perspective, OpsTwin AI functions as an operational control tower for robotic fleets, enabling teams to simulate workflows, evaluate performance, and reduce deployment risk before scaling to physical infrastructure. By separating AI planning from deterministic execution, the architecture mirrors real world robotics systems and provides a clear path from simulation to real-world deployment.

15 Feb 2026